Cost benchmarking is a strategic instrument which can be used to analyse the costs of a product and compare them to those of a competitor or to industry standards. It includes the analysis of various cost components, such as production costs or material costs, with the aim of identifying areas in which the business is investing too much or too little compared to other businesses. The aim of benchmarking here is to see how the business compares to competitors both in terms of quality and price, and to identify specific improvements. The benchmarking analysis also indicates in which areas or function groups a business’s own product is better or more cost-effective than competitor products. You then have the opportunity to create a “best of best” product.

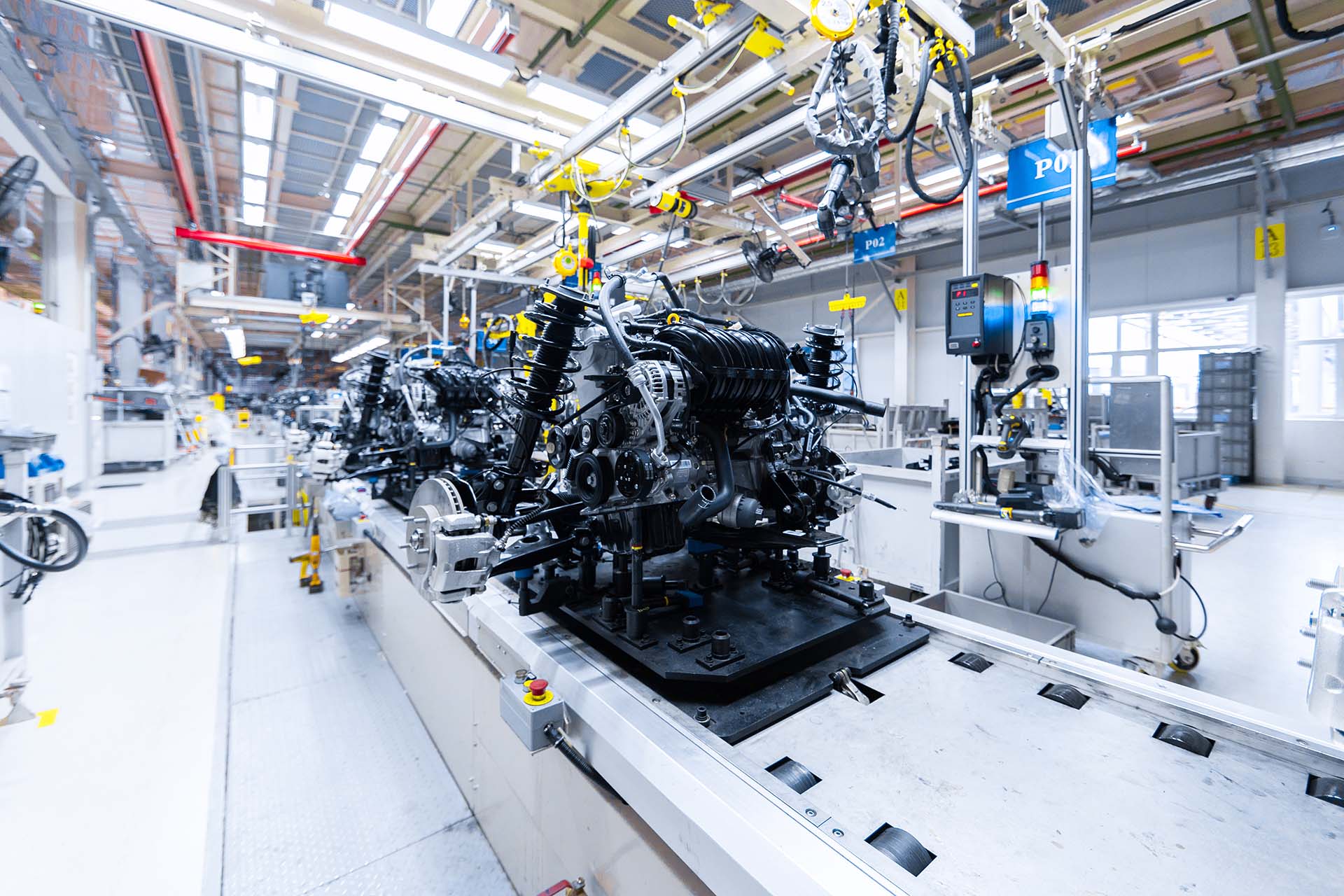

With the costs for the comparison products now transparent, it is possible to ascertain cost advantages and cost potential for the various function groups of the reference product. The solution alternatives range from commercial optimisation (for example, relocating to an alternative production site) to specific changes in processes (for example, using alternative materials or production technologies), through to ideas for concepts for specific products (for example, common parts strategy/modular strategy).