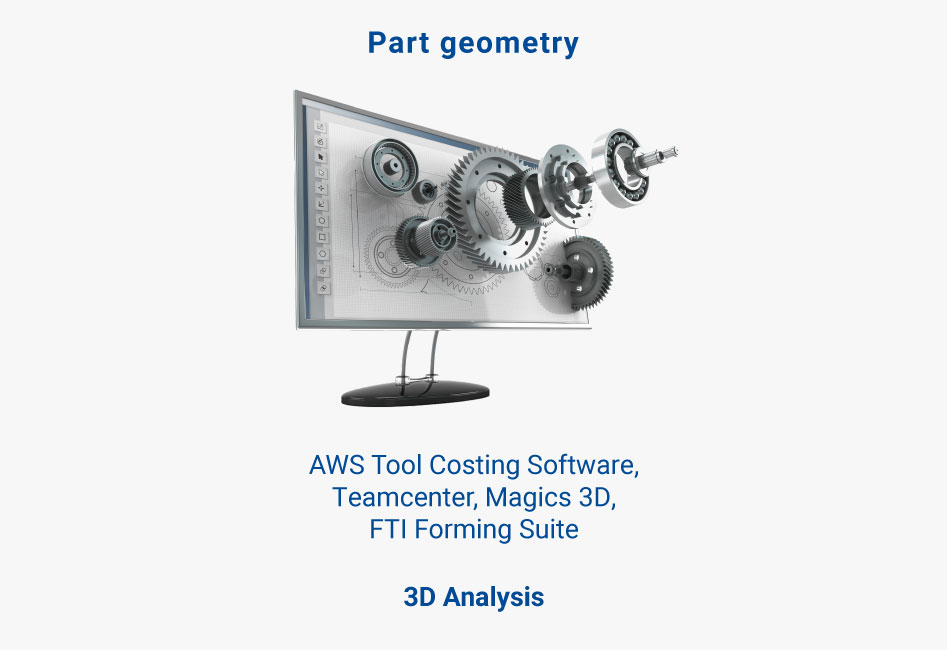

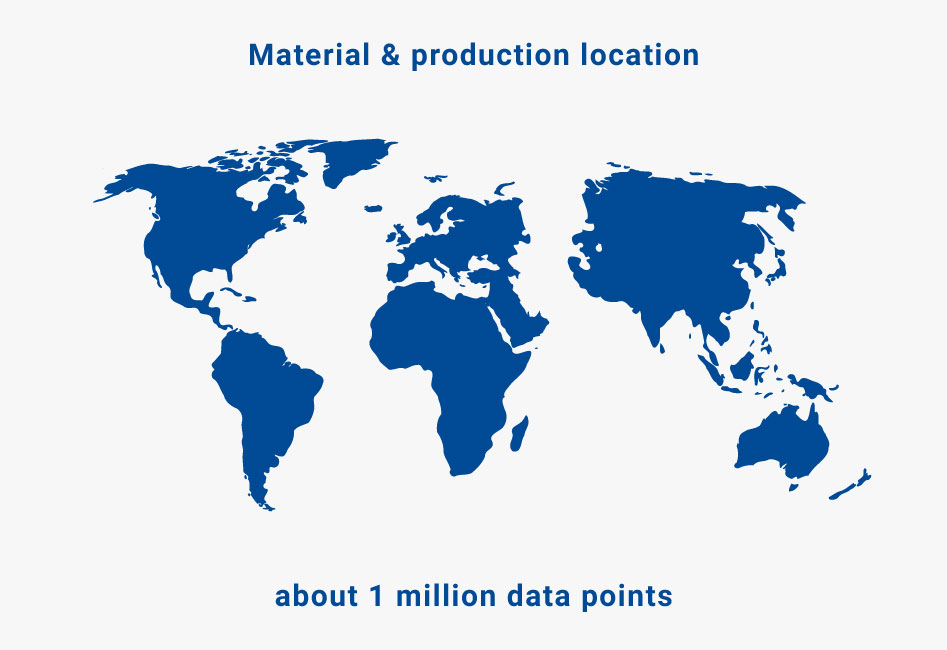

Tool costing is a detailed breakdown of costs which analyses the costs of various tooling concepts. Which components are involved in the tooling concept and how are the costs distributed? How can the technical specifications be implemented in a cost-effective manner (volume, technical requirements, tolerances)? What should be taken into account on procurement? Are there any country-specific factors involved?

In order to obtain certainty about these and many other questions, AWS Tool Costing, together with the data used, can generate useful facts. And with this knowledge at your fingertips, as a business you are better placed in upcoming negotiations. Twenty years of experience in cost engineering has shown us that significant savings can be achieved through the use of tool costing.