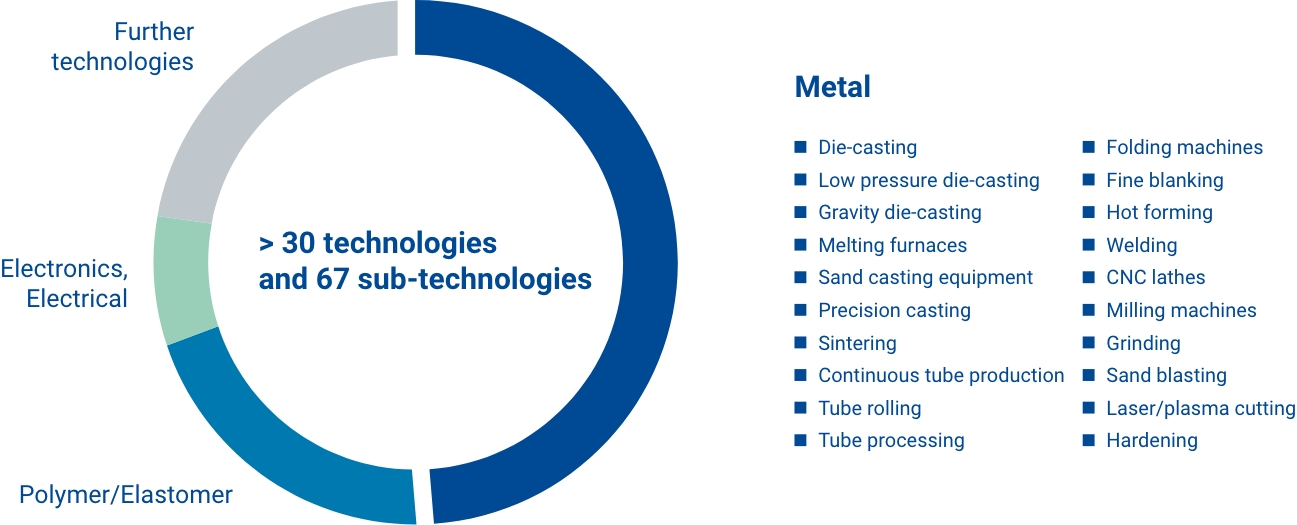

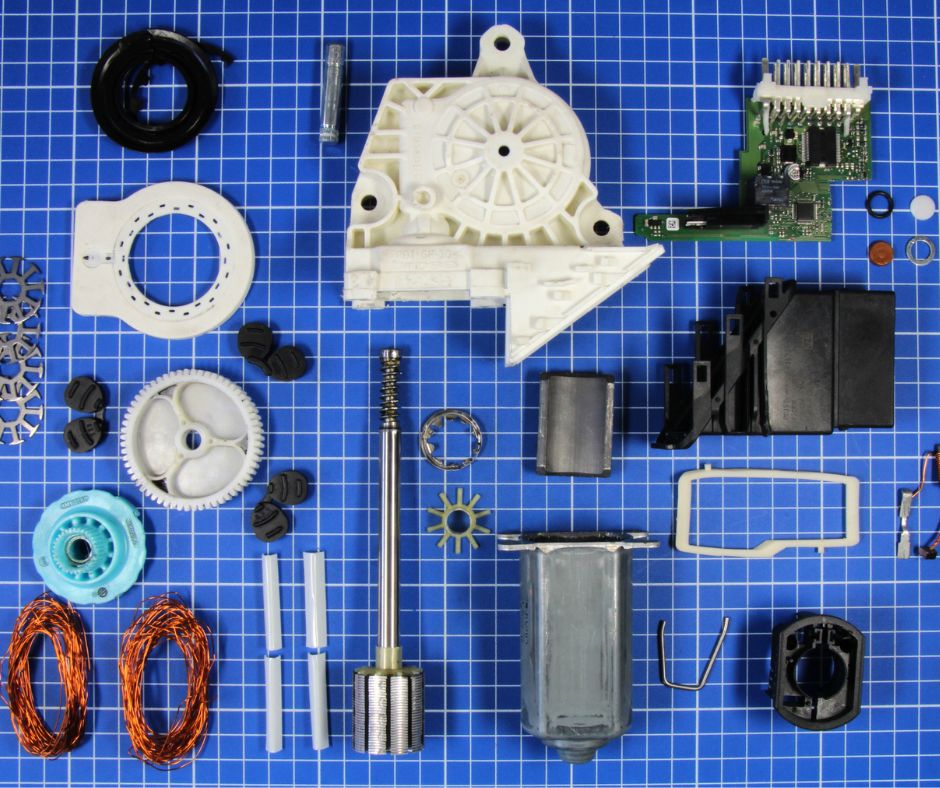

A comprehensive understanding of the composition of a product’s total costs is essential for developing a profitable pricing strategy and ensuring the profitability of individual products. The knowledge gained from product costing enables companies to deploy resources efficiently and make well-founded decisions.

A comparison of your own product costs with the industry average can reveal potential for optimisation, which can be further specified through additional benchmarks. Product costing plays a central role in continuous improvement initiatives by identifying potential savings and efficiency gains. A regular analysis of product costs also strengthens a corporate culture that is geared towards sustainable optimisation and cost efficiency.